Truss

Truss

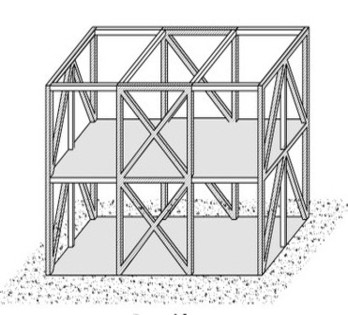

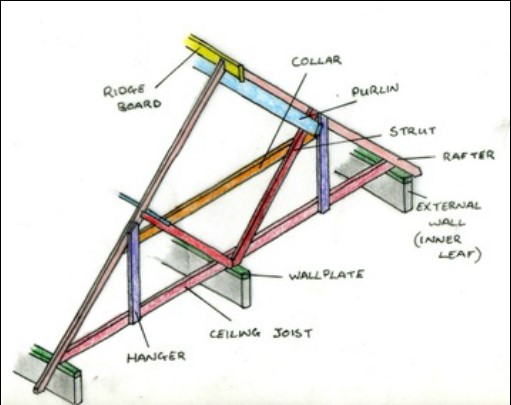

Truss, in engineering, a structural member usually fabricated from straight pieces of metal or timber to form a series of triangles lying in a single plane. It is essentially a triangulated system of straight interconnected structural elements. A truss is made up of a web of triangles joined together to enable the even distribution of weight and the handling of changing tension and compression without bending or shearing. The triangle is geometrically stable when compared to a four (or more) -sided shape which requires that the corner joints are fixed to prevent shearing.

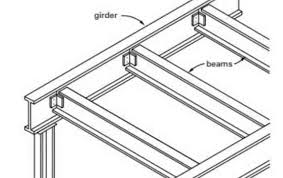

The most common use of trusses is in buildings, where support to roofs, the floors and internal loading such as services and suspended ceilings, are readily provided.

The main reasons for using trusses are:

• Long span

• Lightweight

• Reduced deflection (compared to plain members)

• Opportunity to support considerable loads.

Trusses were probably first used in primitive lake dwellings during the early Bronze Age, about 2500 BC. The first trusses were built of timber. The Greeks used trusses extensively in roofing, and trusses were used for various construction purposes in the European Middle Ages.

Types of trusses:

Trusses comprise assemblies of tension and compression elements. Under gravity loads, the top and bottom chords of the truss provide the compression and tension resistance to overall bending, and the bracing resists the shear forces. A wide range of truss forms can be created. Each can vary in overall geometry and in the choice of the individual elements. Some of the commonly used types are described below

North light truss

This form of truss is usually used for short spans in industrial buildings, and is so called because it allows maximum benefit to be gained from natural lighting by the use of glazing on the steeper north-facing pitch (sometimes referred to as a saw tooth roof).

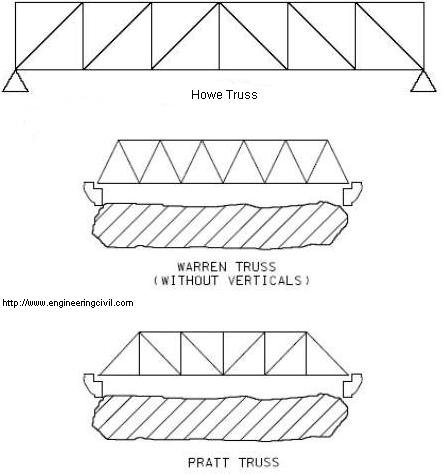

Pratt truss ('N' truss)

Pratt trusses are commonly used in long span buildings ranging from 20 to 100 m in span. In a conventional Pratt truss, diagonal members are in tension for gravity loads. This type of truss is used where gravity loads are predominant.

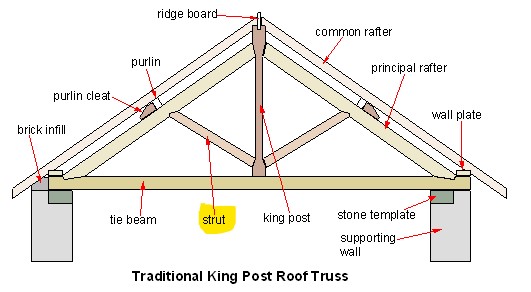

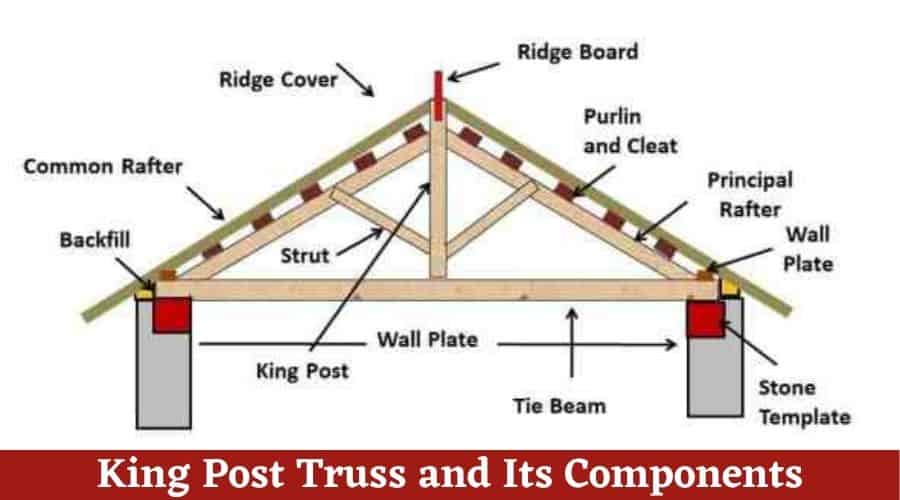

King post truss

Typically made from timber, and spanning up to 8m, king post trusses are commonly used in the construction of domestic roofs. They take the form of a simple triangle, with a vertical member between the apex and the bottom chord. Because king post trusses are made with few materials and a simple design, they come at a lower price point than many other trusses. However, this also means that king post trusses cannot span long distances, so they are better suited for smaller-scale projects.

Warren truss

In this type of truss, diagonal members are alternatively in tension and in compression. The Warren truss has equal length compression and tension web members, and fewer members than a Pratt truss

Queen post truss

Similar to the king post truss, but with diagonal members between the centre of the bottom chord and each of the inclined top chords, queen post trusses can span 10m. The additional posts in a queen post truss make them slightly more expensive than a king post truss.