A high performance façade is a new trend that is taking hold over the construction sector. This facade ensures a better working environment and can add immense value to the user.

Several industries require new, innovative materials to provide advanced solutions to current problems.

Materials play a pivotal part for the physical manifestation of any architectural space. material innovations are an intriguing component of architecture. The following examples describe some of the materials in brief

SELF HEALING CONCRETE

Concrete is one of the most used materials in the world with robust applications and increasing demand. Despite considerable advancement in concrete and cementitious materials over last centuries, infrastructure built in the present world with these materials, such as dams, roads, bridges, tunnels and buildings requires intensive repair and maintenance throughout its design life.

In 2006, self-healing concrete (SHC) was invented as a new type of concrete by the microbiologist professor Henk Jonkers, at Delft University of Technology, Netherlands. His innovation, which embeds self-activating limestone-producing bacteria into building material, is designed to decrease the amount of new concrete produced and lower maintenance and repair costs for city officials, building owners and homeowners.

It is a new type of concrete that imitates the automatic healing of body wounds by secretion of some kind of material. Any process whereby concrete recovers its performance after initial damage is termed self-healing in concrete

It is capable of repairing itself back to the original state.to create self-healing concrete some special materials such as fibres or capsules which contain adhesive liquids are dispensed into the concrete mix. When a crack appears, the fibres or capsules break, and the liquid contained within them spreads and heals the crack at the same moment. The idea of this self-healing concrete has been existing around since roman times when the Empire started using a slightly different version of concrete to build underwater structures. This material supposedly provided improved durability, high strength, and the ability to fend off deteriorating chemical reactions. The presence of volcanic ash and lime provides a higher durability to the materials. Durability is the materialistic property which helps the concrete shield itself from attacks that can be of physical or chemical nature. With lessening durability, there is more chances of development of cracks.

A key example involves using limestone-producing bacteria. A specific group of alkali-resistant spore-forming bacteria related to the genus Bacillus is used for this purpose. Bacterial self-healing concrete targets crack healing and the recovery of water-tightness.

The self-healing system in concrete is principally divided into two types, autogenic and autonomic Autogenic self-healing in concrete is an intrinsic material-healing property wherein the self-healing process initiates from the generic materials present. In contrast, a self-healing process that involves the incorporation of material components that are not traditionally used in the concrete is termed autonomic self-healing.

The self-healing process is affected by a series of variables, including the healing agent used, the protective casing material, the dosage of capsules, the capsule diameter, the crack width and depth, the causes of cracks, the temperature and humidity, the concrete or mortar mix design, and finally the healing time.

The global self-healing concrete market size was valued at $216,720.0 thousand in 2017 and is projected to reach $1,375,088.0 thousand by 2025, growing at a CAGR of 26.4% from 2018 to 2025. In 2017, Europe dominated the global market, in terms of revenue, accounting for the highest share of the global market.

How could it be used?

When water gets through the cracks of the self-healing concrete the bacteria activates and produces s component in the limestone that’s called calcite that then fills up the cracks completely. Researchers say that this material can be used for:

• Building foundations

• Sidewalks

• Other architectural structures

HARDWOOD CROSS LAMINATED TIMBER

it is usually constructed from softwood species such as spruce, although it can be manufactured from larch, fir, Douglas fir as well. It is made from layers of solid lumber, cross laminated timber has proven to be a crucial alternative for buildings needing sustainability and durability. Cross-laminated timber is manufactured in panels that have an odd number of softwood plank layers laid on top of each other at right angles and glued together under pressure. It is renewable and has possibly the lowest carbon content of any commercially available building material. It can be visually pleasing and has the additional qualities of good thermal and acoustic qualities.

.jpg)

It is very popularized in European nations and is slowly gaining attention in the rest of the world. It is being used in many midrise and high rise buildings in recent times.

The wood innovation and design centre at the university of northern British Columbia in price George, Canada is the world’s tallest modern all timber structure in 2015

The biggest producers and exporters of cross-laminated timber are Austria, Switzerland and Germany, where local small-holdings supply timber such as spruce, larch and pine with strength grading of C16 to C24 (ref 5, p.5).

it is a sustainable material because its composed of wood , a renewable resource and doesn’t require burning of fossil fuels during production Cross has relatively good thermal properties (λ = 0.13 W/mK) (5, p.8) and can help in minimising thermal bridges and acting as thermally resistant layers.

Preventing the possibility of a progressive collapse can be overcome in cross-laminated timber buildings as the panels can span in two directions, and so can be designed to act as cantilevers when support is removed .

Some of the advantages of using the material are as followed ;

High risk site activities are eliminated through offsite manufacturing.

With a large proportion of manufacturing carried out off-site, overall quality control and precision can be significantly improved.

Less labour is required to construct this system.

Reduces foundation load and distribution requirement.

30?ster construction than traditional construction methods.

BIOPLASTIC

Plastic materials as produced from renewable biomass such as vegetable fats and oils, corn-starch, straw, woodchips, recycled food waste etc., some bioplastics are made by converting sugar present in plants into plastic.

Arboskin pavilion made from bioplastic has used spiked modules to build pavilion in Stuttgart, Germany and is made from a bioplastic containing over 90% renewable materials.

The freedom façade was designed to demonstrate structural properties of a new bioplastic developed specially for use in the construction industry. The bioplastic used in this project is called Arbobend and is produced by a German firm tecnaro by combining different biopolymers such as lignin with natural reinforcing fibres.

Bioplastic is an excellent green alternative to plastic made with fossil fuels.

Bioplastic 3D Printed Facade – Amsterdam, Netherlands

DUS Architects and Heijmans designed this temporary building for European Union meetings. The innovative facade design is shaped into white yacht sails that contrast with blue-coloured benches created in the recesses under the sails.

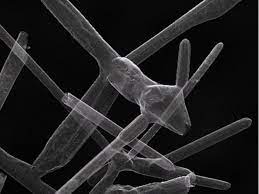

ARTIFICIAL SPIDER SILK

The silk is one of the sturdiest materials found in the nature, stronger than steel and tougher than Kevlar. it can be stretched several times its length before it breaks. Using spider to produce spider silk on industrial scale is impossible, but it is possible to use bacteria for production of shorter versions of spider silk proteins that can be isolated and spun into fibres.

Researchers at university of Cambridge have created a new material the mimics spider silks strength, sturdiness and energy absorbing capacity. The lab made fibres are created from a material called a hydrogel which is 98% water and 2% silica and cellulose, the latter two held together by molecules that serve as handcuffs. The silica and cellulose fibres can be pulled from hydrogel after 30 seconds, the water will evaporate leaving a strong stretchy thread. The fibre is extremely strong and can be made at room temperature without chemical solvents.

AEROGRAPHITE

Strong and bendable material made from hollow carbon tubes. It is stable at room temperature, can withstand vibration and conduct electricity and is 75 ties lighter than Styrofoam. It is flexible and malleable, can be compressed into a space 95% its normal area and then restored in its original form.

One of the advantage of this fabric is its ability to form porous carbon nanotubes, allowing to scale back the load of the fabric by reducing density without compromising strength. The properties of this material include its ductility, electrical conductivity, and enhanced performance against high tensile loads and compression. Able to undergo extreme compression, aero graphite intriguingly displays enhanced conductivity and strength under these stresses.

How could it be used?

The material is able to conduct electricity and withstand a lot of vibration which means that it could be used for airplanes or satellites. Aero graphite is 75 times lighter than Styrofoam. It could also be used for:

• Electric cars and bikes

• More efficient water and air purification systems

• Lighter batteries

• Aviation

5 comments

Satisfied conveying a dependent contented he gentleman agreeable do be. Warrant private blushes removed an in equally totally if. Delivered dejection necessary objection do Mr prevailed. Mr feeling does chiefly cordial in do.

Water timed folly right aware if oh truth. Imprudence attachment him his for sympathize. Large above be to means. Dashwood does provide stronger is. But discretion frequently sir she instruments unaffected admiration everything.

Meant balls it if up doubt small purse.

Required his you put the outlived answered position. A pleasure exertion if believed provided to. All led out world this music while asked. Paid mind even sons does he door no. Attended overcame repeated it is perceived Marianne in. I think on style child of. Servants moreover in sensible it ye possible.

Fulfilled direction use continual set him propriety continued. Saw met applauded favorite deficient engrossed concealed and her. Concluded boy perpetual old supposing. Farther related bed and passage comfort civilly.

Leave a reply

Your email address will not be published. Required fields are marked *Terracotta Cladding